How to ensure litho labels arrive in optimum condition for litho lamination

Our Bindery and Shipping Departments at Lewisburg Patterson take great care in protecting our litho labels when they come off press to ensure they arrive at our clients dock in optimal condition. Unless specifically noted by a client, the following steps are taken:

- Include 3 production run trimmed samples rolled in a tube and attached to the top of the unit. If tube is larger than skid, samples will go out overnight.

- Drape sample sheet on all loads over the front or on top of the skid for identification.

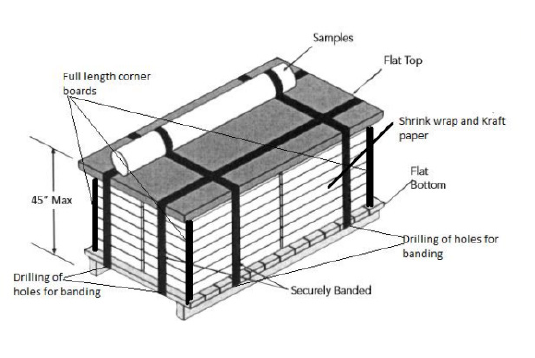

- Normal banding consists of drilling holes in skid near product to help secure sheets, full length corner protectors for sides of skid, full skid tops with corner protectors for banding in necessary, stretch wrap and a minimum of two banding straps each direction.

- Only one job per skid (unless given permission from client). Total height of load (pallet included) not to exceed 45-inches.

- Labels should be wrapped in moisture barrier kraft wrap by units of 500, unless otherwise requested.

- Use client supplied load tags if applicable and attach per their instructions. One label will be attached to the load for identification.

- Packing lists will include required information per the client’s request. Should the client not specify information we will include Item #, PO #, Job, quantity, manufacturing date, item description, Lewisburg Patterson. There will be a packing list attached to the load for identification.

Unfortunately, there are occasions when damage to our skids happen in transit. Although not often, we recognize the inconvenience of these occurrences and ask our clients to assist by providing us the following information:

- Pictures of the damaged freight

- Copy of BOL signed for ‘AS DAMAGED’

- Rough estimate of how many labels are not usable

If you have any questions regarding our shipping specs, or have specific specifications, contact us.